DentaMile Bite Splint Workflow: Precision Meets Efficiency

A Seamless Digital Solution for High-Quality Bite Splints

The DentaMile Bite Splint Workflow integrates premium resins, intelligent software, and dependable 3D printing systems into a validated process, ensuring high-quality results for dental professionals and their patients.

Streamlined Design with DentaMile connect

Our cloud-based CAD/CAM software, DentaMile connect, simplifies the creation of custom-fit bite splints:

- Automated Margin Line feature: Accelerates design by up to 90%, enabling same-day splint production.

- Virtual Articulator: Allows precise adjustments during design, reducing the need for post-production modifications.

- User-Friendly Interface: Facilitates efficient workflows via guided design steps, saving time for both clinicians and patients.

Let’s make splints easier!

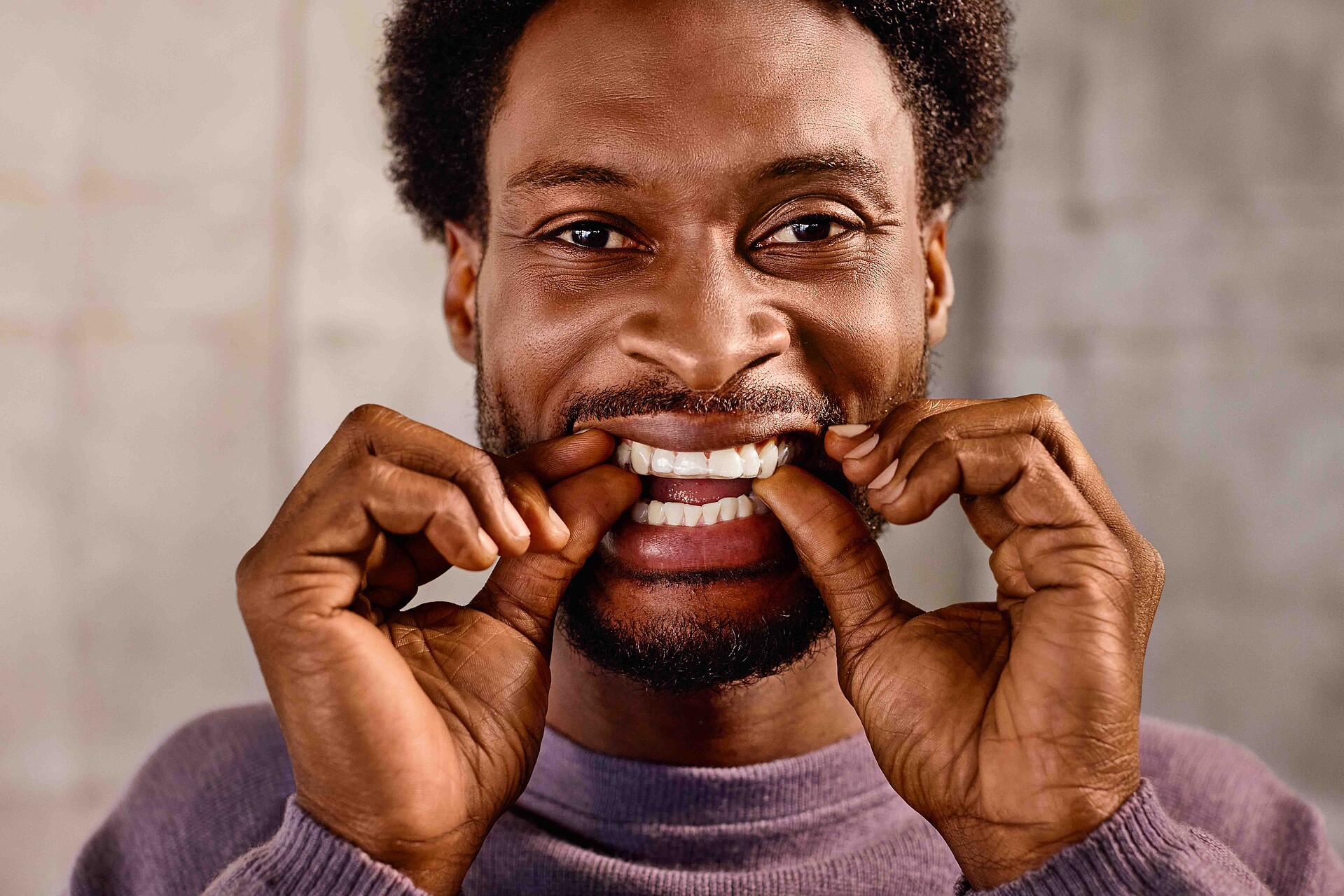

The DentaMile Advantage: Benefits at a Glance

The DentaMile 3D Bite Splint Workflow offers am easy and efficient way to produce high-quality bite splints—delivering speed, precision, and satisfaction for both dental clinics and laboratories.

- Precise fit enhances patient wearability

- Clear, transparent material provides outstanding aesthetics

- Optimally integrated workflow components ensure comfort, flexibility, and splint stability

- High-precision 3D printing enables an accurate fit in just one appointment

- Smart software features and automation streamline processes, giving clinics and labs more time to focus on what matters most: patient care

A Win-Win-Win for All

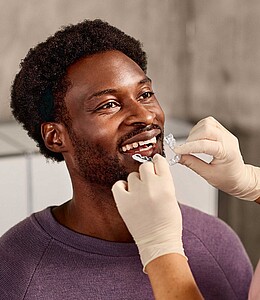

Whether you’re a dentist, dental technician or a patient, the DentaMile Bite splint Workflow offers:

everyone benefits from the bite splint workflow and high-quality results―everyone wins.

- Efficiency: Automated design and fast printing save valuable time.

- Quality: Combines durability with comfort for superior splints.

- Satisfaction: Enhanced comfort and aesthetics lead to higher patient approval.

Splint Workflow

-

DMG DentaMile Splint WorkflowPrecise splints